Heat Treatment

Advanced Vacuum Heat Treatment Solutions at Invacua

At Invacua, we pride ourselves on delivering cutting-edge vacuum heat treatment services, utilizing two state-of-the-art vacuum furnaces designed to meet a wide range of industrial needs. Our advanced equipment and expertise ensure precision, reliability, and superior results for components requiring heat treatment in a controlled, oxygen-free inert environment.

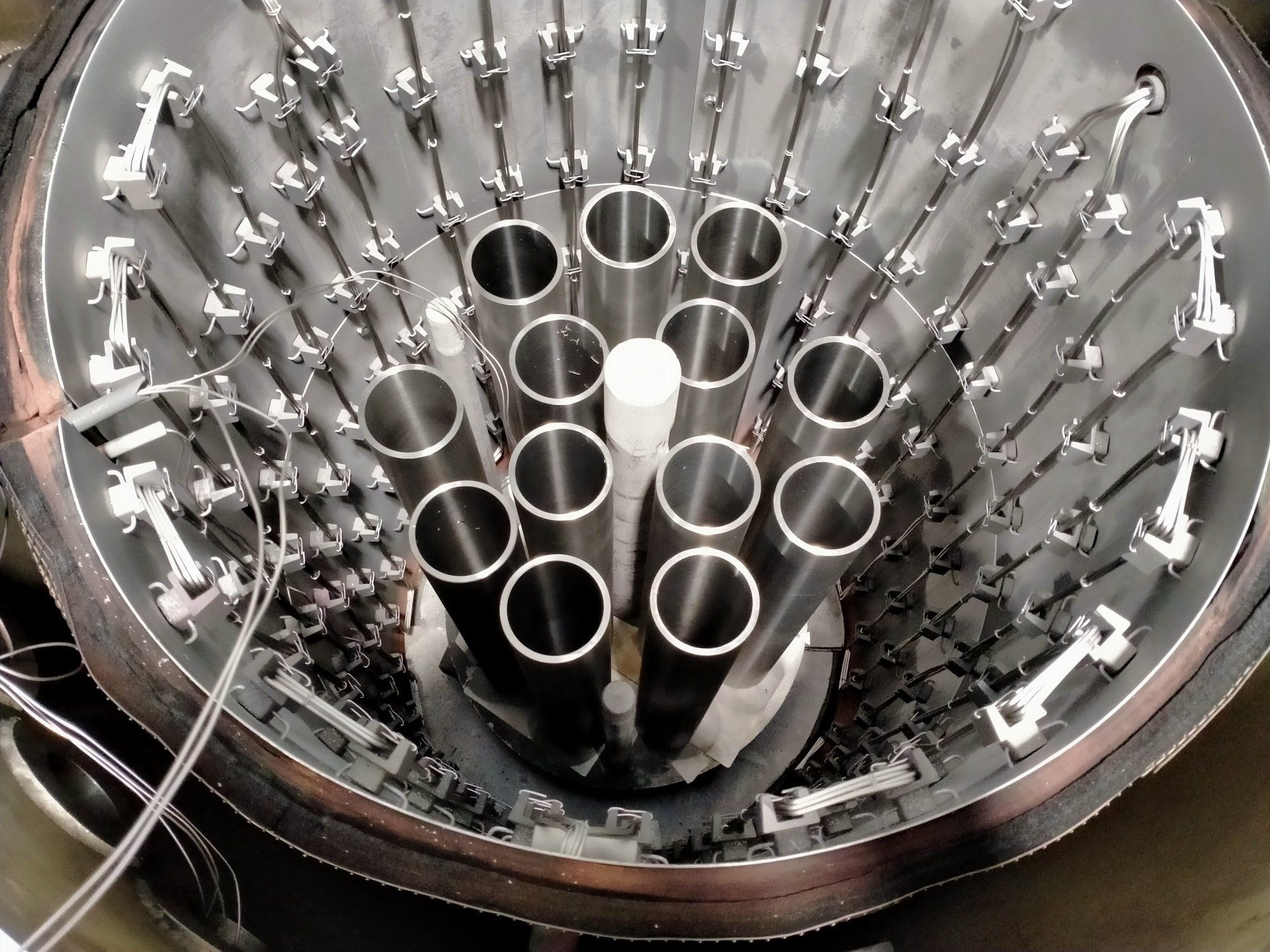

High-Performance Vacuum Furnaces

Our two vacuum furnaces are engineered to achieve temperatures up to 1200°C, making them suitable for a variety of heat treatment processes, including annealing, demagnetising, UHV outgassing and stress relieving. These furnaces are designed to handle diverse materials, such as stainless steel, titanium, copper and superalloys, which are commonly used in aerospace, automotive, medical and nuclear industries. The high-temperature capability ensures that components achieve the desired metallurgical properties for the specific application.

Ultra-High Vacuum for Superior Results

One of the standout features of our furnaces is their ability to operate at ultra-high vacuum levels, down to 1×10⁻⁷ mbar. This level of vacuum ensures an oxygen-free, inert environment, preventing oxidation and contamination of the treated components. By eliminating reactive gases, our vacuum furnaces produce cleaner surfaces and obtain the desired integrity of the material's microstructure. This is particularly critical for high-precision components, such as accelerator components, medical implants, and instrumentation, where even minor surface or material contamination can compromise performance.

Rapid Cooling for Enhanced Efficiency

Both furnaces are equipped with a rapid cooling function, which significantly reduces processing times and enhances material properties. This feature allows for controlled quenching using inert gases, such as nitrogen or argon, to cool components more quickly which can aid in maintaining the desired material microstructure. Rapid cooling is essential for achieving specific properties, such as increased hardness or improved toughness in a range of materials. The ability to tailor cooling rates ensures that our clients receive components with optimized mechanical properties for their specific applications.

Monitoring & Control

To guarantee consistent and repeatable results, our furnaces are fitted with calibrated thermocouples and vacuum gauges. The thermocouples provide accurate temperature monitoring, ensuring that the heat treatment process adheres to precise specifications. Meanwhile, the vacuum gauges allow for real-time monitoring of the furnace's internal pressure, ensuring that the ultra-high vacuum environment is maintained throughout the treatment cycle. This level of precision is critical for industries where strict quality standards, such as those set by aerospace, medical and nuclear regulatory bodies, must be met.

Applications of Vacuum Heat Treatment

Vacuum heat treatment is a versatile process with applications across numerous industries. At Invacua, we cater to clients requiring treatments for:

· Aerospace, Defence & Nuclear Components: Machined components are vacuum heat treated to alter their microstructure which in turn changes their mechanical properties. Characteristics such as hardness, stress, strength, toughness, ductility and magnetic properties are altered to enhance performance in hostile operational environments.

· Particle Accelerator & Vacuum Components: Vacuum vessels and experimental components are vacuum stoved to obtain cleanliness, relieve stress and obtain specific magnetic permeability requirements.

treated

Why Choose Invacua?

Our commitment to quality and innovation sets us apart in the field of vacuum heat treatment. By combining advanced furnace technology with meticulous process control, we deliver components that meet the most demanding specifications. Whether you need small-batch processing or large-scale production, our team of experts works closely with clients to develop tailored heat treatment solutions that optimize performance and cost-efficiency.

For more information about our vacuum heat treatment services or to discuss your specific needs, contact Invacua today. Let us help you achieve superior results with our leading vacuum furnace technology.